19/7/2019, Friday, Sunny.

After over10 years of accumulation in China's power battery industry, there has been a very big improvement, in particular, the understanding and knowledge of the power battery. With a succession of battery fire, power battery safety is a sensitive topic, but also a topic can not be avoided.

The following factors need to be considered before designing a power battery: Battery modules and battery pack (system) assembly ability design, mountability design, maintainability design, adjustable design, recycling and easy-to-dability design.

If these performance problems are not solved, the lithium batteries will become "time bombs".

Lithium-ion battery is mainly composed of six parts: positive, aluminum foil, negative pole, copper foil, diaphragm and electrolyte. The electrolyte inside the battery contains a large amount of organic matter, such as ethylene carbonate, diethylene carbonate, and dimethyl phosphate. These guys all come with their own explosive properties, with the words "Stay away from the fire" written on their faces.

In addition, once the positive and negative poles of the battery short-circuit, it will be a lot of heat, and even sparks, so people will naturally think of a thing to separate the positive and negative poles, so the introduction of diaphragm. Once the battery diaphragm is thinned, the film is damaged and the problem becomes serious.

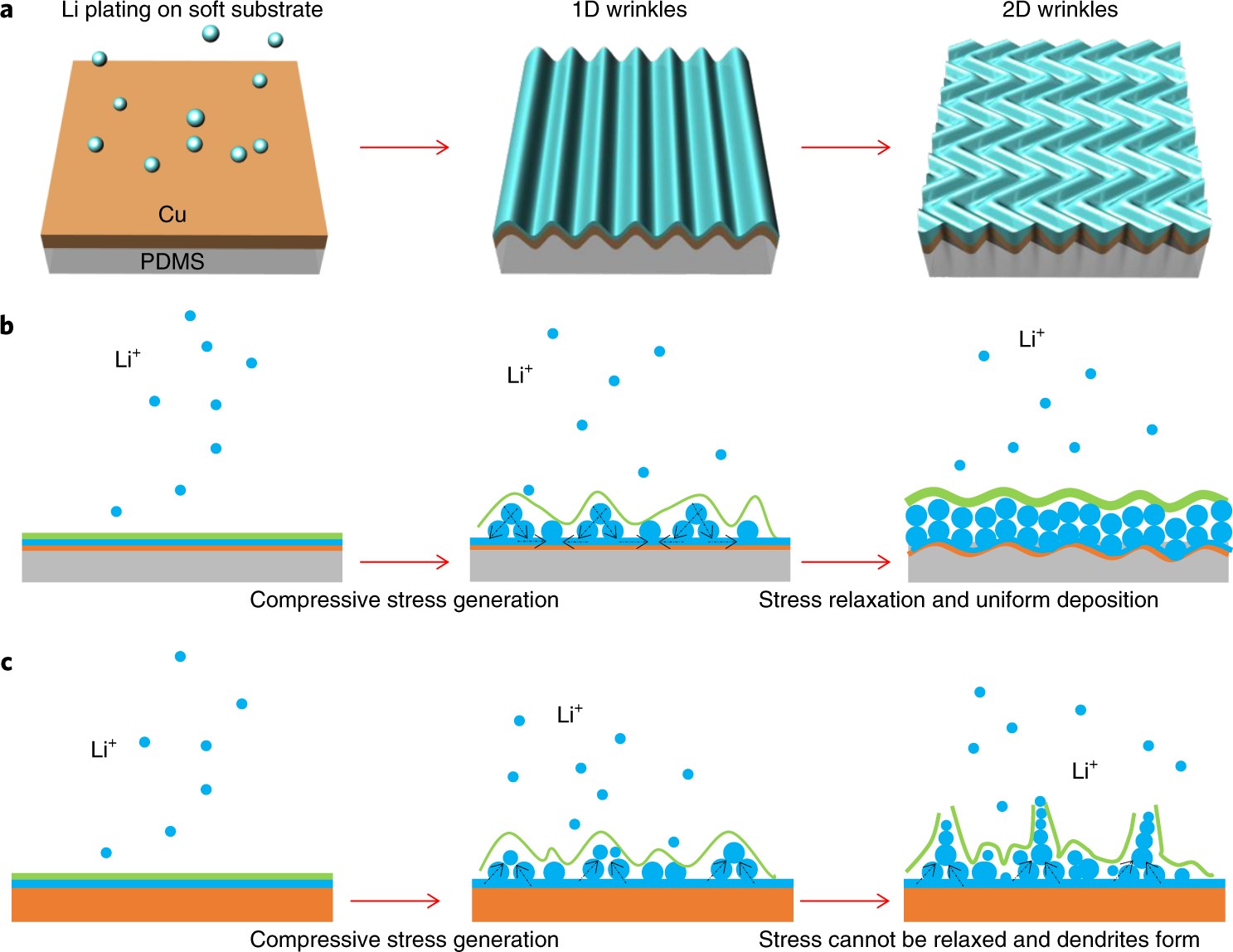

Lithium battery itself also hides the hidden dangers of piercing the diaphragm, this kind of phenomenon is called "Lithium Dendrite". During the usage of lithium battery, the electrode surface will form some small burrs, these small burrs are called "Dendrite", and the bigger of dendrites, it will eventually penetrate the diaphragm, resulting in battery short circuit.

Therefore, the thinner diaphragm, combustible electrolyte, the dendrites will grow up, then high temperature material decomposition will automatically separate oxygen, the entire lithium battery is like a "time bombs".

The safety of the battery system must be solved by battery cells, which must be designed with more stable materials and a safer design to ensure battery safety.

In terms of safety of battery cells, the choice of thicker diaphragm should not be achieved by reducing the thickness of the diaphragm in the design of the battery cells to improve energy density.

Safety management when charging a battery pack is key! Because the power lithium battery group use is the most critical and the most core issue: First, safety, second, life, especially in the fast charging, the battery group battery differences increase, how to solve the battery pack life, facing great challenges.

The key point of battery pack is safety management when battery pack is charging. Because the most concerning issues is battery safety and cycle life when we talk about the usuage of power battery. Especially when battery in fast charging, the differences between each battery cells will increase a lot. Then how to solve the issue of battery pack cycle life, we are facing great challenges.

In addition to the battery's workmanship and quality, one of the most critical issues is the safety control and thermal management technology when we talk about the factors that affect the safe use and cycle life of the battery. Without perfect battery pack safety control and thermal management technology, battery safety and long-life cycle can not be guaranteed, therefore, the power battery charging management system and the battery itself is as important as the safety.

After over10 years of accumulation in China's power battery industry, there has been a very big improvement, in particular, the understanding and knowledge of the power battery. With a succession of battery fire, power battery safety is a sensitive topic, but also a topic can not be avoided.

How do we know power batteries?

The following factors need to be considered before designing a power battery: Battery modules and battery pack (system) assembly ability design, mountability design, maintainability design, adjustable design, recycling and easy-to-dability design.

If these performance problems are not solved, the lithium batteries will become "time bombs".

Lithium-ion battery is mainly composed of six parts: positive, aluminum foil, negative pole, copper foil, diaphragm and electrolyte. The electrolyte inside the battery contains a large amount of organic matter, such as ethylene carbonate, diethylene carbonate, and dimethyl phosphate. These guys all come with their own explosive properties, with the words "Stay away from the fire" written on their faces.

In addition, once the positive and negative poles of the battery short-circuit, it will be a lot of heat, and even sparks, so people will naturally think of a thing to separate the positive and negative poles, so the introduction of diaphragm. Once the battery diaphragm is thinned, the film is damaged and the problem becomes serious.

Lithium battery itself also hides the hidden dangers of piercing the diaphragm, this kind of phenomenon is called "Lithium Dendrite". During the usage of lithium battery, the electrode surface will form some small burrs, these small burrs are called "Dendrite", and the bigger of dendrites, it will eventually penetrate the diaphragm, resulting in battery short circuit.

|

| [Photos from Internet] |

Therefore, the thinner diaphragm, combustible electrolyte, the dendrites will grow up, then high temperature material decomposition will automatically separate oxygen, the entire lithium battery is like a "time bombs".

How to ensure the safety of the power battery system?

The safety of the battery system must be solved by battery cells, which must be designed with more stable materials and a safer design to ensure battery safety.

In terms of safety of battery cells, the choice of thicker diaphragm should not be achieved by reducing the thickness of the diaphragm in the design of the battery cells to improve energy density.

Safety management when charging a battery pack is key! Because the power lithium battery group use is the most critical and the most core issue: First, safety, second, life, especially in the fast charging, the battery group battery differences increase, how to solve the battery pack life, facing great challenges.

The key point of battery pack is safety management when battery pack is charging. Because the most concerning issues is battery safety and cycle life when we talk about the usuage of power battery. Especially when battery in fast charging, the differences between each battery cells will increase a lot. Then how to solve the issue of battery pack cycle life, we are facing great challenges.

In addition to the battery's workmanship and quality, one of the most critical issues is the safety control and thermal management technology when we talk about the factors that affect the safe use and cycle life of the battery. Without perfect battery pack safety control and thermal management technology, battery safety and long-life cycle can not be guaranteed, therefore, the power battery charging management system and the battery itself is as important as the safety.

|

| Photo from Internet |

评论

发表评论